With the development of the economy, plastic product production is constantly increasing and so is the amount of plastic waste. In the face of the increasing amount of waste plastic, its disposal will also become a social concern. Getec Group has designed a waste plastic pyrolysis plant(machine/equipment) that can solve the problem of waste plastic disposal. Getec waste plastic pyrolysis machine can turn waste plastic into pyrolysis oil, combustible gas, and carbon black.

Oil Yield of Different Kinds Of Waste Plastics

| Types of Plastic | Coming From | Oil Yield |

| PE | films, bottles, electrical insulating materials, handbags, bottles/calcium bottles, daily necessities, etc. | 95% |

| Polypropylene (PP) | films, plastic rope, tableware, pots, barrels, furniture, bags, caps, car bumpers, etc. | 90% |

| Polystyrene(PS) | electrical appliances, stationery, cups, food containers, appliance housings, electrical fittings, foam products, toys, etc. | 90% |

| ABS plastic | N/A | 40% |

| Pure white plastic sheeting | N/A | 70% |

Note: Different plastics have different oil yields, Getec Group can help you choose the right equipment model according to your requirements and provide you with supporting solutions.

Waste Plastic Pyrolysis Plant For Sale

Getec plastic pyrolysis plant price is from low. When choosing a waste plastic pyrolysis plant, you need to consider many factors, such as its model, processing capacity, working method, footprint, etc. Below we list Getec’s hot-selling plastic recycling machine models, you can choose the plastic pyrolysis equipment model you want according to your actual situation. Then please leave a message with your detailed needs below, and we will contact you in time to provide you with the most suitable customized plastic treatment solution for you.

Waste Rubber

Oil Sludge

Waste Plastics

What End Products Will You Get?

Pyrolysis Oil

Usage:

1. Be used as fuel

2. Directly used as non-standard diesel

3. Used in cement factory, steel factory, power factory, chemical factory, boiled factory, etc.

Combustible Gas

Usage:

Used for pyrolysis process heating.

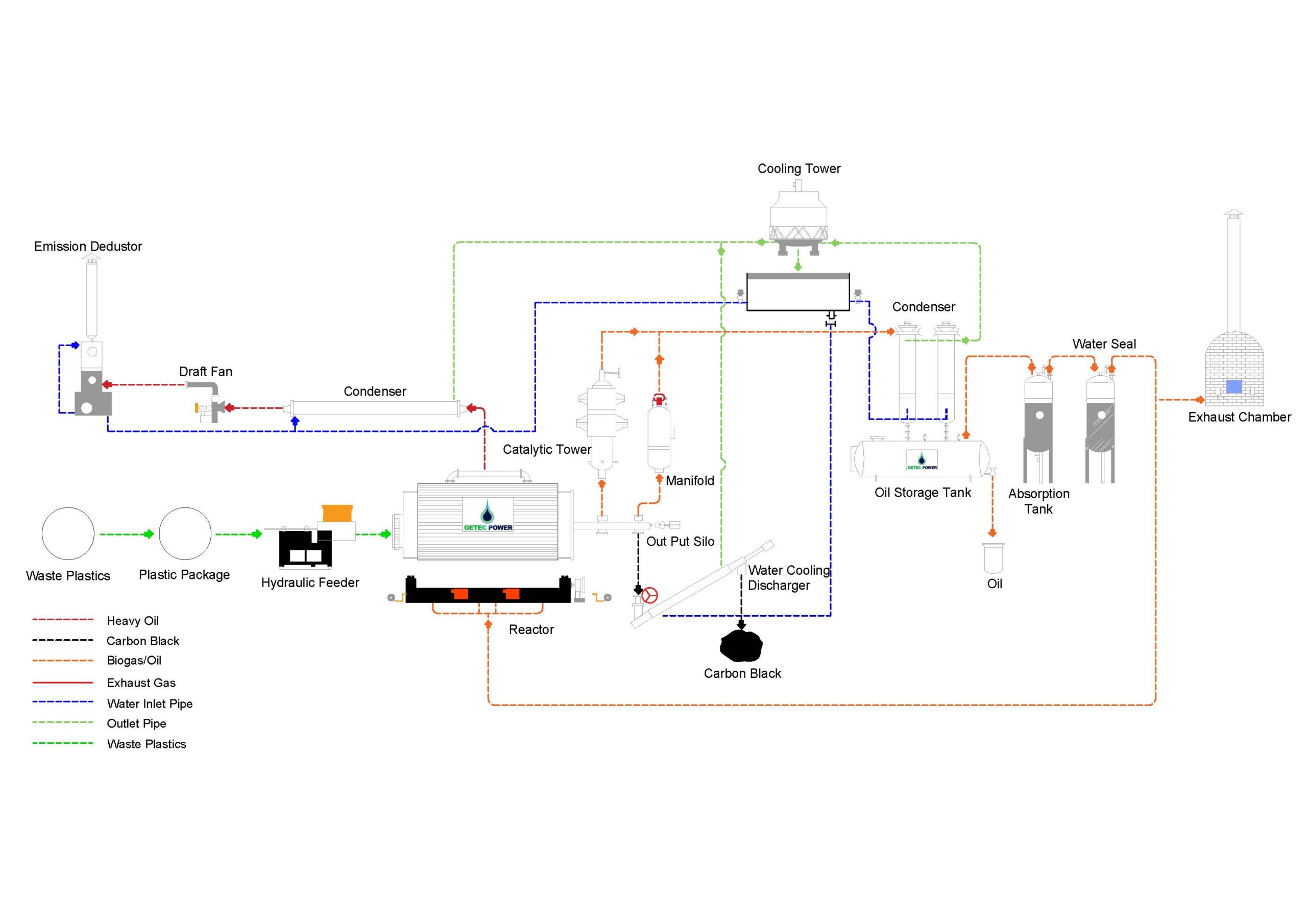

Flow Chart Of The Waste Plastic Pyrolysis Plant

Getec oil sludge pyrolysis plant is safe and environmentally friendly. The pyrolysis furnace is heated outside and operated by the oxygen-depleted thermal pyrolysis process. The furnace is sealed to ensure that no gas escapes during the production process, improving the efficiency of the thermal pyrolysis process, while fundamentally eliminating unsafe hazards and secondary pollution caused by gas escaping during the production process.

1. Feeding

The screw feeder feeds the plastic scrap automatically into the reactor. However, if you choose a batch-type machine, the feeding will be manually operated. When the internal temperature of the pyrolysis reactor reaches the relevant temperature after heating, oil gas will be generated.

2. Pyrolysis

The oil gas will enter the manifold and the heavy particles in the oil and gas will be liquefied to heavy oil and fall into the heavy oil tank; the light oil gas will be liquefied to fuel oil by the condenser and retained in the fuel oil tank.

3. Condensing

The combustible gas produced during the pyrolysis process will be desulfurized and purified in a hydraulic seal and then recycled in the combustion chamber as a heating source.

4. Treatment of flue gas and residues

The fumes generated during the heating of the reactor will first be cooled in a flue condenser. Afterward, it will enter the dust removal system and spray tower for dust removal, scrubbing, water spraying, ceramic ring adsorption, and activated carbon absorption. Finally, it will be discharged safely, complying with EU environmental and emission standards.

Advantages of Getec Pyrolysis Plant

We adopt the spiral water-cooled slag discharge method, which is highly automated, airtight and safe, more environmentally friendly, and cleaner.

High degree of automation

Three-in-one box condensing design, the equipment integrates a water tank, condensing, and water seal in one, which is easy to install, covers a small area, and saves space.

Three-in-one condensing system

Diversified models can meet customers’ needs from 0.5 tons to 30 tons per day, and can meet customers’ needs at different stages from testing project feasibility to large-scale commercial solutions.

Meet different needs

According to the customer’s demand for processing raw materials, we can use matching catalysts. We adopt the special catalyst for plastic cracking developed by ourselves, which can effectively improve the yield and quality of fuel oil.

System matching catalyst

We can customize the size and shape of the reactor door according to customer needs to meet the feeding requirements of different raw materials and provide more diversified and convenient feeding methods.

Customized demand

We can design corresponding project 3D drawings for customers according to their sites to help them visualize the site layout and appearance more intuitively.

Provide design support

Why You Should Choose Getec Group?

Your Personal Professional Sales Consultant

- Getec sales manager contacts customers in a timely manner, patiently listen to every customer’s needs, and ensures that problems are solved;

- We will propose a professional business plan according to the customer’s national and regional policies, venues and other factors;

- Genuinely looking out for our customers and not giving them inappropriate advice just to sell one more machine.

Contact Us

Please fill in the form below and submit your inquiry. We will reply to you within 2 hours.

Please specify your requirement by referring to the following aspects:

1. What kind of solution will meet your demand? (Key point)

2. What kind of material and expected end product are you planning to have? (Right solution begins from material and product)

3. When is the project supposed to be running? (Key info for A-Z project programming)

4. Budget for machinery purchasing? (Key info for right model)

5. Points that you really focus on. (Customized service from our project consultant)