Oil Sludge Pyrolysis Plant For Sale

It is well known that oily sludge is poorly dewatered, difficult to treat, and contains harmful substances such as PAHs and heavy metals, which are radioactive pollutants to the environment. But Getec oil sludge pyrolysis plant can solve its pollution to the environment while turning hazardous oily sludge into useful substances such as pyrolysis oil, oily carbon residue, and sygas.

What Kind of Oily Sludge Will You Process?

Choosing the right oil sludge pyrolysis plant is also important for your investment project. Getec group has over 15 years of experience in selling oil sludge pyrolysis equipment. Over the past decades, Getec’s pyrolysis plants have been sold to 10+ customers around the world, mainly in Thailand and South East Asian countries etc. Getec oil sludge pyrolysis equipment can be your first choice.

Oil Based Drilling Mud

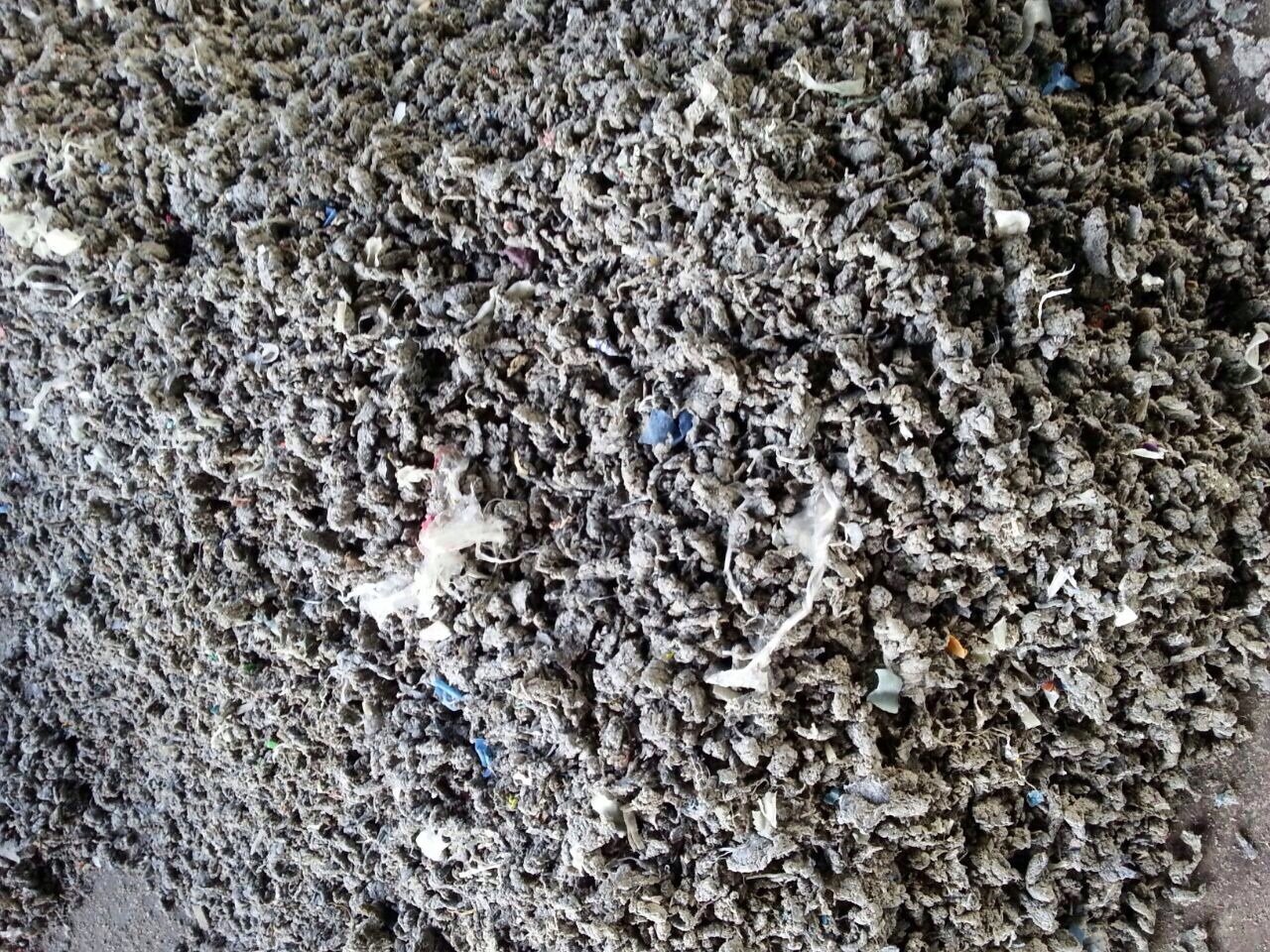

Enginee Sludge

Oilfield Sludge

Which Model do You Prefer?

Choosing the right oil sludge pyrolysis plant is also important for your investment project.

BLL-30 Fully Continous Oil Sludge Pyrolysis Plant

Capacity: 8~10 tone/day

Working Method: batch

Feature: small investment project

Weight: 44 tonnes

Reactor Size: D2.6m*L6.6m

Total Power: 30kw/h

Installation Area Request(L*W*H): 30m*10m*8m

Detailed Parameters of Getec Oil Sludge Pyrolysis Plant

| Model | BLJ-3 | BLJ-6 | BLJ-10 | BLL-16 | BLL-30 | |

| Capacity | 1-3t/d | 4-6t/d | 8-10t/d | 12-16t/d | 30-35t/d | |

| Working Process | Batch | Batch | Batch | Semi-continuous | Fully continuous | |

| Reactor Size | φ1400*4900mm | φ2200*6000mm | φ2600*6600mm | φ2800*7100mm | φ1800*18500mm | |

| Reactor Material | Q245R | Q245R | Q245R | Q245R | 310S stainless steel | |

| Drive System | 350 reducer+4kw drive motor | 400 reducer+5.5kw drive motor | 400 reducer+5.5kw drive motor | 500 reducer+7.5kw drive motor | ZQH650-50 reducer+15kw frequency conversion motor | |

| Land (L*W*H) | 18m*4.2m*6m | 30m*12m*8m | 30m*13m*8m | 33m*13m*8m | 70m*20m*10m | |

| Power | 16.65kw | 37.85kw | 44.3kw | 55.6kw | 256kw | |

| Burner | 2*200,000 kcal | 2*300,000 kcal | 2*300,000 kcal | 2*400,000 kcal | 2.5 million kcal per set | |

| Total Weight of Shipped Materials | About 18t | About 24.5t | About 28t | About 34.5t | About 150t | |

| Number of Containers | 1*40HQ | 1*40FR+1*40HQ+1*20 GP | 1*40FR+2*40HQ | 1*40FR+2*40HQ | 25m*8m bulk cargo+8*40HQ | |

| Noise (dB) | ≤60 | ≤60 | ≤60 | ≤60 | ≤60 | |

| Heating Materials | Fuel oil (including tyre/plastic pyrolysis oil), natural gas, LPG, diesel, etc. | |||||

| Condensing System | Vertical Condenser | φ426*3000 Single piece condensing area 7.58m2 | φ630*3600 Single piece condensing area 17.8m2 | φ630*3600 Single piece condensing area 17.8m2 | φ820*3600 Single piece condensing area 35.6m2 | φ920*3200 2 sets of vertical condenser |

| 3-in-1 Condenser | 3000*2200*2250 Condensing area 17.51m2 | 5800*2260*2500 Condensing area 35.85m2 | 5800*2260*2500 Condensing area 35.85m2 | 8000*2260*2500 Condensing area 49.5m2 | ||

Processable Raw Materials & Oil Yield of Getec Pyrolysis Plant

- Waste rubber: oil yield of 20%-40%, including waste cable sheaths, rubber shoe soles, rubber gloves, etc.;

- Oil sludge: oil yield of 20%-50%, including oil based drilling mud, enginee sludge, oilfield sludge etc.;

- Waste plastics: oil yield of (20%-80%), including waste acrylic (PMMA), PE, PP, etc.

Waste plastic

Waste Rubber

Oil Sludge

Waste Plastics

Detailed oil yield of specific raw materials

| Raw materials | Specific materials | Oil yield |

| waste tires | Truck tires | 45%-50% |

| Car tires | 40-45% | |

| Bicycle/motorcycle tires | 30%-35% | |

| Waste rubber | Rubble cable | 25%-35% |

| Sole of shoes | 25%-35% | |

| Mixed sole | 20%-30% | |

| Sneakers | 20%-30% | |

| Waste chemical fiber carpe | 30% | |

| PMMA | 40% | |

| Miscellaneous rubble | 35% | |

| Oil sludge | 20%-50% |

Note: The oil yield of different raw materials is different, Getec Group will equip you with the right equipment according to your needs and provide supporting solutions.

What End Products You Will Get?

Pyrolysis Oil

Usage:

1. Be used as fuel

2. Directly used as non-standard diesel

3. Used in cement factory, steel factory, power factory, chemical factory, boiled factory, etc.

Combustible Gas

Usage:

Used for pyrolysis process heating.

Why You Should Choose Getec Oil Sludge Pyrolysis Plant?

Getec pyrolysis units are not only of objective quality but also exported all over the world, such as in the Philippines, Indonesia, Thailand. Here we will introduce the production process, unique advantages, and some national cases of Getec pyrolysis equipment

Oil Sludge Pyrolysis Process Introduction

Getec oil sludge pyrolysis plant is safe and environmentally friendly. The pyrolysis furnace is heated outside and operated by the oxygen-depleted thermal pyrolysis process. The furnace is sealed to ensure that no gas escapes during the production process, improving the efficiency of the thermal pyrolysis process, while fundamentally eliminating unsafe hazards and secondary pollution caused by gas escaping during the production process.

Oil Sludge Pyrolysis Plant Advantages

Getec oil sludge pyrolysis plant has been specially designed to be easy to install, dismantle and transport.

Getec oil sludge pyrolysis plant has been specially designed to be easy to install, dismantle and transport.

Safe, economical and environmentally friendly design. The use of special insulation materials, fast heating system, rotating reactor and exhaust gas recovery system makes it safe, continuous and efficient heating, saving fuel and running costs, easy to operate, and recycling of exhaust gas.

Quiet production environment. Low power and low noise during production runs, creating a good workshop environment for you.

Global Cases of Getec Oil Sludge Pyrolysis Plant

Getec BLJ-3 Skid-Mounted Oil Sludge Pyrolysis Plant

On 18 May 2021, the Getec BLJ-16 oil mud pyrolysis plant was assembled. The raw material of choice for this customer is oil sludge with an oil yield of approximately 20-55%. The customer visited Getec’s factory headquarters and was very satisfied with the quality of our products.

Getec BLL-16 Pyrolysis Plant has been shipped to Nigeria in March 2022. The machine type requested by this customer is the BLL-16, with a daily capacity of approximately 20 tonnes per day. This customer, who has never bought our products before, said he would like to experience them first. If the quality of our products is up to scratch, he will continue to work with us in the future.

Eco-friendly design

No wastewater discharge: The heat exchange water of the condenser is separated from the oil and gas. There is no direct contact between oil and gas. When the water inside the water seal enters the combustion chamber it can be used as fuel to provide heat for the reactor.

No exhaust gas emissions: excess condensate gas goes directly into a special exhaust chamber. It is not emitted into the air.

Safety design

The pyrolysis oil equipment has multiple points to observe temperature, pressure, and liquid level. When high temperature or high pressure appears, the alarm device will be ringing. Then, you can find the problem quickly and adjust them in time.

Eco-friendly design

The oil and gas recovery system is designed to collect combustible gases. They are then used to provide heat for the reactor. This will result in significant savings in fuel costs.

The heavy oil burner is designed to burn heavy oil to provide heat for the reactor heating. It reduces fuel costs considerably.

Why You Should Choose Getec Group?

Your Personal Professional Sales Consultant

- Getec sales manager contacts customers in a timely manner, patiently listen to every customer’s needs, and ensures that problems are solved;

- We will propose a professional business plan according to the customer’s national and regional policies, venues and other factors;

- Genuinely looking out for our customers and not giving them inappropriate advice just to sell one more machine.

Trustworthy Company

- Strong company strength: more than 15 years of manufacturing experience; more than 30 employees and more than 5 engineers; 1,000 m² of factory space and 100 m² of office space

- Unique company advantages: support for three-party inspection; support for online/on-site installation services; provision of after-sales documentation such as installation videos/installation manuals/operation manuals/maintenance manuals.

- Getec leadership values each client and is actively involved in each order.

- More than 6 after-sales engineers are available to provide installation, commissioning and operator training services to each and every customer.

Contact Us

Please fill in the form below and submit your inquiry. We will reply to you within 2 hours.

Please specify your requirement by referring to the following aspects:

1. What kind of solution will meet your demand? (Key point)

2. What kind of material and expected end product are you planning to have? (Right solution begins from material and product)

3. When is the project supposed to be running? (Key info for A-Z project programming)

4. Budget for machinery purchasing? (Key info for right model)

5. Points that you really focus on. (Customized service from our project consultant)