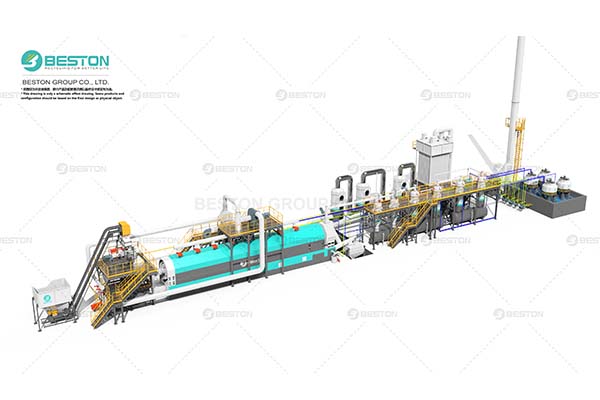

Tyre Pyrolysis Plant For Sale

Tyre pyrolysis plant is an environmentally friendly machine that helps you dispose of old tyres and rubber. Pyrolysing used tyres can not only minimize their impact on the environment but also bring you huge profits. Tyre pyrolysis plants can process all sizes of tyres and rubber with low input costs and low energy consumption, and get a high return on investment. There is no doubt that this is a relatively good investment.

Global Cases of Beston Tyre Pyrolysis Machine

Choosing the right tyre pyrolysis plant is also important for your investment project. Beston group has over 9 years of experience in selling tyre pyrolysis equipment. Over the past decades, Beston’s tyre pyrolysis plants have been sold to 100+ countries around the world, including Korea, Vietnam, Indonesia, Thailand, UK, Malaysia, Philippines, Turkey, Bangladesh, Spain, Chile, Dominica, Mexico, Brazil, Saudi Arabia, Egypt, Paraguay, etc. Beston tire pyrolysis equipment can be your first choice.

BLJ-10 Tyre Pyrolysis Plant Installed In Indonesia

BLL-16 Tyre Pyrolysis Plant Installed In the Netherlands

BLJ-16 Tyre Pyrolysis Plant Trial Run In Egypt

BLJ-16 Tyre Pyrolysis Plant Shipped To Nigeria

Models of Tire Pyrolysis Plants For Sale

Choosing the right tyre pyrolysis plant is also important for your investment project. Beston group has over 9 years of experience in selling tyre pyrolysis equipment. Over the past decades, Beston’s tyre pyrolysis plants have been sold to 100+ countries around the world, including Korea, Vietnam, Indonesia, Thailand, UK, Malaysia, Philippines, Turkey, Bangladesh, Spain, Chile, Dominica, Mexico, Brazil, Saudi Arabia, Egypt, Paraguay, etc. Beston tire pyrolysis equipment can be your first choice.

BLJ-6 Batch Tyre Pyrolysis Plant

Capacity: 8~10 tone/day

Working Method: batch

Feature: small investment project

Weight: 44 tonnes

Reactor Size: D2.6m*L6.6m

Total Power: 30kw/h

Installation Area Request(L*W*H): 30m*10m*8m

Detailed Parameters of Beston Tyre Pyrolysis Plant

| Model | BLJ-3 | BLJ-6 | BLJ-10 | BLL-16 | BLL-30 | |

| Capacity | 1-3t/d | 4-6t/d | 8-10t/d | 12-16t/d | 30-35t/d | |

| Working Process | Batch | Batch | Batch | Semi-continuous | Fully continuous | |

| Reactor Size | φ1400*4900mm | φ2200*6000mm | φ2600*6600mm | φ2800*7100mm | φ1800*18500mm | |

| Reactor Material | Q245R | Q245R | Q245R | Q245R | 310S stainless steel | |

| Drive System | 350 reducer+4kw drive motor | 400 reducer+5.5kw drive motor | 400 reducer+5.5kw drive motor | 500 reducer+7.5kw drive motor | ZQH650-50 reducer+15kw frequency conversion motor | |

| Land (L*W*H) | 18m*4.2m*6m | 30m*12m*8m | 30m*13m*8m | 33m*13m*8m | 70m*20m*10m | |

| Power | 16.65kw | 37.85kw | 44.3kw | 55.6kw | 256kw | |

| Burner | 2*200,000 kcal | 2*300,000 kcal | 2*300,000 kcal | 2*400,000 kcal | 2.5 million kcal per set | |

| Total Weight of Shipped Materials | About 18t | About 24.5t | About 28t | About 34.5t | About 150t | |

| Number of Containers | 1*40HQ | 1*40FR+1*40HQ+1*20 GP | 1*40FR+2*40HQ | 1*40FR+2*40HQ | 25m*8m bulk cargo+8*40HQ | |

| Noise (dB) | ≤60 | ≤60 | ≤60 | ≤60 | ≤60 | |

| Heating Materials | Fuel oil (including tyre/plastic pyrolysis oil), natural gas, LPG, diesel, etc. | |||||

| Condensing System | Vertical Condenser | φ426*3000 Single piece condensing area 7.58m2 | φ630*3600 Single piece condensing area 17.8m2 | φ630*3600 Single piece condensing area 17.8m2 | φ820*3600 Single piece condensing area 35.6m2 | φ920*3200 2 sets of vertical condenser |

| 3-in-1 Condenser | 3000*2200*2250 Condensing area 17.51m2 | 5800*2260*2500 Condensing area 35.85m2 | 5800*2260*2500 Condensing area 35.85m2 | 8000*2260*2500 | ||

Processable Raw Materials & Oil Yield of Beston Pyrolysis Plant

- Waste tyres: oil yield of 30%-50%, including machinery tyres, bicycle tyres, motorbike tyres and other tyres;

- Waste rubber: oil yield of 20%-40%, including waste cable sheaths, rubber shoe soles, rubber gloves, etc.;

- Sludge oil: oil yield of 20%-50%, including oil mud, oil sludge, etc.;

- Waste plastics: oil yield of (20%-80%), including waste acrylic (PMMA), PE, PP, etc.

Waste Tyres

Waste Rubber

Oil Sludge

Waste Plastics

Detailed oil yield of specific raw materials

| Raw materials | Specific materials | Oil yield |

| Waste tire | Truck tires | 45%-50% |

| Car tires | 40-45% | |

| Bicycle/motorcycle tires | 30%-35% | |

| Waste rubber | Rubble cable | 25%-35% |

| Sole of shoes | 25%-35% | |

| Mixed sole | 20%-30% | |

| Sneakers | 20%-30% | |

| Waste chemical fiber carpe | 30% | |

| PMMA | 40% | |

| Miscellaneous rubble | 35% | |

| Oil sludge | 20%-50% |

Note: Beston tyre pyrolysis plant cost starts from $49,000, affected by model, capacity, and configuration.

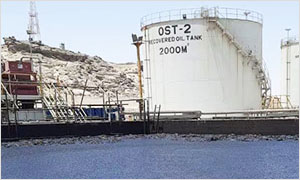

End product – High Economic Value & Multiple Applications

Pyrolysis Oil

Usage:

1. Be used as fuel

2. Directly used as non-standard diesel

3. Used in cement factory, steel factory, power factory, chemical factory, boiled factory, etc.

Carbon Black

Usage:

1. Be used as fuel

2. Directly used as non-standard diesel

3. Used in cement factory, steel factory, power factory, chemical factory, boiled factory, etc.

Steel

Usage:

1. Be sold directly;

2. To produce steel bars and rods in the steel-making factory.

Combustible Gas

Usage:

Used for pyrolysis process heating.

Tire Pyrolysis Process Introduction

Feeding: The automatic screw feeder (optional) pushes the raw materials to the furnace door.

Heating: The reactor is heated after the feeding.

Oil and gas generation: When the internal temperature of the reactor reaches 180°C, pyrolysis oil and combustible gas will be generated, and then enter the manifold. After that, the heavy particles of the oil gas will be collected in the sludge tank, while the light oil and gas will enter the condenser and then be liquefied into pyrolysis oil. In the end, it will be stored the tank and that’s the oil you can get.

Unique Features of Beston Tyre Pyrolysis Machines

Beston tyre pyrolysis machine has a modular design that can be split into a feed system, a heating system, a pyrolysis reactor, a condensation system, a dust removal system, and a discharge system. This design has the following characteristics:

- Improve the versatility and interchangeability of the various components of the pyrolysis system.

- Enrich more feasible designs for different customers’ needs, enabling customized solutions.

- Easy to deliver, assemble and maintain.

Discharging System

Pyrolysis Reactor

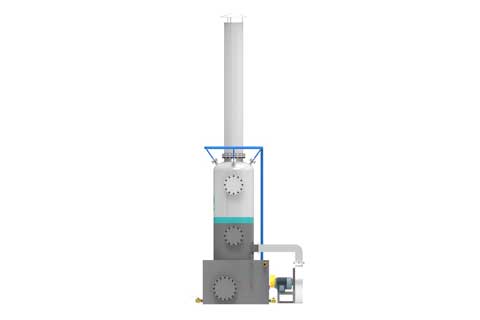

Condensing System

Also, another three unique and innovative designs of Beston’s tire pyrolysis plant have enabled it to occupy a leading position in the market, making Beston one of the top three tire pyrolysis equipment manufacturers in China. And it also ensures that you don’t have to worry about environmental certifications and safety issues.

Eco-friendly design

No wastewater discharge: The heat exchange water of the condenser is separated from the oil and gas. There is no direct contact between oil and gas. When the water inside the water seal enters the combustion chamber it can be used as fuel to provide heat for the reactor.

No exhaust gas emissions: excess condensate gas goes directly into a special exhaust chamber. It is not emitted into the air.

Safety design

The pyrolysis oil equipment has multiple points to observe temperature, pressure, and liquid level. When high temperature or high pressure appears, the alarm device will be ringing. Then, you can find the problem quickly and adjust them in time.

Eco-friendly design

The oil and gas recovery system is designed to collect combustible gases. They are then used to provide heat for the reactor. This will result in significant savings in fuel costs.

The heavy oil burner is designed to burn heavy oil to provide heat for the reactor heating. It reduces fuel costs considerably.

Choose Beston as Tyre Pyrolysis Plant Supplier

Your Personal Professional Sales Consultant

- Beston sales manager contacts customers in a timely manner, patiently listen to every customer’s needs, and ensures that problems are solved;

- We will propose a professional business plan according to the customer’s national and regional policies, venues and other factors;

- Genuinely looking out for our customers and not giving them inappropriate advice just to sell one more machine.

Reliable Product

- ISO and CE certification

- Strict quality inspection system. Tyre pyrolysis equipment meets inspection standards before leaving the factory

- Customized design with a wide product line. Tyre pre-treatment, capacity, dust removal and exhaust emissions can all be custom designed

- Layout/production drawings provided; and the ability to make changes based on customer needs

- Direct tyre pyrolysis equipment manufacturers, no middlemen, affordable prices

- Free cost and profit estimating services are available

Trustworthy Company

- Strong company strength: more than 9 years of manufacturing experience; more than 300 employees and more than 50 engineers; 16,000 m² of factory space and 2,400 m² of office space

- Unique company advantages: support for three-party inspection; support for online/on-site installation services; provision of after-sales documentation such as installation videos/installation manuals/operation manuals/maintenance manuals.

- Beston leadership values each client and is actively involved in each order.

- More than 60 after-sales engineers are available to provide installation, commissioning and operator training services to each and every customer.

Contact Us

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Pre-sale Service

Please specify your requirement by referring to the following aspects:

1. What kind of solution will meet your demand? (Key point)

2. What kind of material and expected end product are you planning to have? (Right solution begins from material and product)

3. When is the project supposed to be running? (Key info for A-Z project programming)

4. Budget for machinery purchasing? (Key info for right model)

5. Points that you really focus on. (Customized service from our project consultant)