Tire Shredder For Sale

If you want to recycle used tires, welcome to choose Beston Tire Pretreatment System. Its function is mainly to process waste tires, rubber, and other raw materials into tire blocks, tire strips, or tire powder through related crushing equipment. The tire pretreatment system generally includes cut circle machines, slicing machines, tire removers, and other equipment. We can match different types of equipment to meet the needs of customers, and tailor-made solutions for customers.

Types of Tire Shredders

If you want to recycle old tires, firstly you need to cut them into smaller pieces to make the following process easier. Beston tire crusher is the important pre-processing equipment in the scrap tyre recycling process. It can crush whole tires into rubber pieces of up to 50mm or 30-200 mesh rubber powder. Here are the types and pictures of the tire shredders. You can click here to contact us for more details.

Waste Tyres

Capacity:40 tires

Weight: 500Kg

Functions: Seperate the tread from the lip

Tire Collector

Capacity:200 tires

Weight: 400Kg

Functions: Collect multiple tires into one

Tire Slicing Machine

Capacity:2.5 tonne

Weight: 850Kg

Functions: It can cut the tire into strips

Tire Blocker

Capacity:40 tires

Weight: 500Kg

Functions: Seperate the tread from the lip

Tire Cutter

Capacity:10-60 tires tonne

Weight: 1200Kg

Functions: Cut the tire into large pieces

Tire Remover

Capacity:50-60 tires

Weight: 1500Kg

Functions: Seperate the wire from the tire

Tire Shredder

Capacity:2.5 tonne / 4 tonne

Weight: 7500 / 16000kg

Functions: Treat the tires into 5-6cm blocks

Tire Grinder

Capacity:0.3/0.5/1/2/3.5 t

Weight 1.25w~3.3w kg

Function: Tire blocks into 5-26 purpose powder

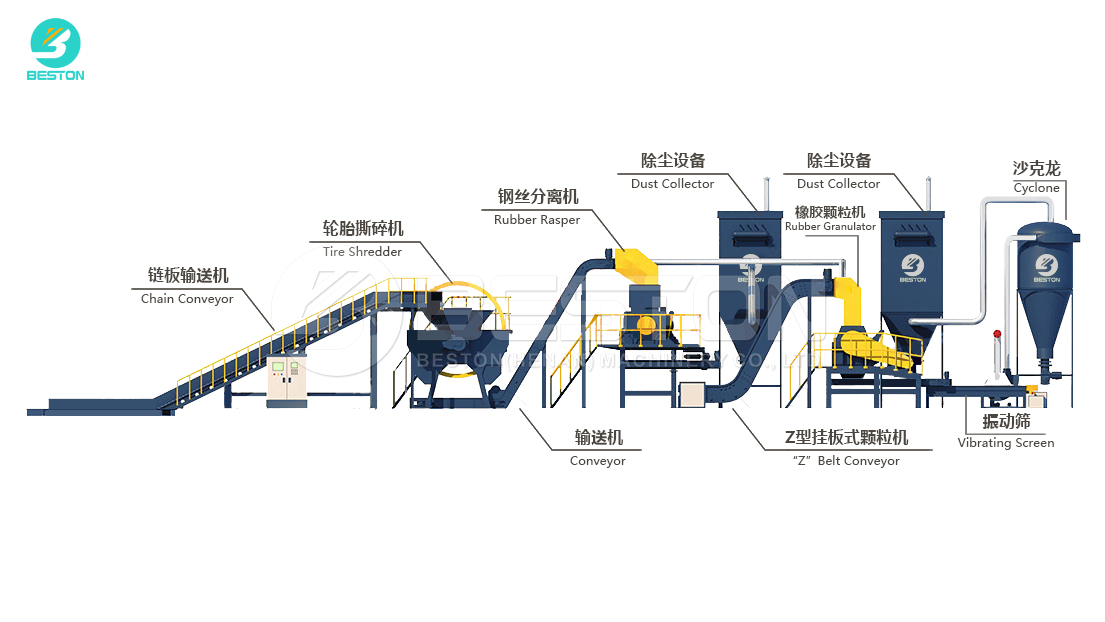

Customized Tire Treatment Scheme Show

This scheme is an automatic scheme to process the whole tire into tire powder. And it is a customized plan for our Egypt customers. He hopes to dispose of used tires into rubber powder. After carefully reading our plan, he is very satisfied and successfully placed an order. If you also have a need in this regard, please contact us for a free customized solution.

Main supporting equipment Selected

| Model | Production/h | Weight | Power | Tire required |

| Tire cutter | 10-60tires | 1200kg | 4+0.75kw | 650-1200mm |

| Wire remover | 50-60tires | 1500kg | 18.5kw | 650-1200mm |

| Tire shredder | 2.5/4t | 7500/16000kg | Determined by model | |

| Tire grinder

line | 0.3/0.5/1/2/3.5t | 1.25w~

3.3w kg | Determined by model | |

Main Parameters Selected

| Voltage | 220V/380V (customization) |

| Tire cutter Size | 2900*1040*1800mm |

| Wire remover | 1500*1550*1150mm |

| Tire shredder Model | 800 model/1200 mode |

| Tire grinder Model | 350/400/450/560/660 model |

Note: This automatic solution is suitable for projects with a high degree of automation and a large amount of processing. And the project is more complicated, tire shredder and tire grinder have different models and processing capacities. And we have 8 models of shredders and grinders. It is good for you to contact us to get a customized scheme.

Customized Tire Treatment Scheme Show

Beston not only produces high-quality tire shredders for China but is also able to supply to the whole world. Over the past decades, Beston’s tyre shredders have been sold to 100+ countries around the world, including Malaysia, Brazil, Indonesia, Iraq, Turkey. Namibia, Zimbabwe, Ghana, Colombia, Egypt, Algeria, Saudi Arabia, Vietnam, USA, etc. We are widely praised by customers and honored at home and abroad, looking forward to having you as one of them.

Beston Tire Shredder Was Shipped To Brazil

After an in-depth inspection of Baxter crushers and a video tour of our plant, this Brazilian customer decided to purchase a pyrolysis plant as well as a crusher. The crusher has now been loaded onto a truck and is waiting to be shipped to Brazil!

Operation Processes of the Tyre Shredders

Overview of Tyre Shredder for Sale

Before shredding, all tyres will be sent to the wire puller, which will pull out all the wire from the tyres. Then by using a powerful cutting torque, the scrap tyres or tyre fragments are continuously cut, squeezed and rolled at room temperature. And the tyres will be cut into pieces and begin to be screened. The eligible pieces are transferred out and the larger pieces are returned to the cutting chamber for a new round of cutting together with the rest of the material. In the end, you will have tyre chips measuring 50 x 50 mm.

Note: As our tyre shredder is a pre-treatment plant for scrap tyre pyrolysis plants and tyre rubber powder lines, we usually use a belt conveyor to transfer the qualified tyre chips to the next step in the process.

Operation Video of Beston Tire Shredder

Application of Tyre Shredder

Sports surfacing: running tracks, school playing fields, swimming pools and garden paths, footpaths, bowling alleys, kindergarten playing and recreation grounds, tennis and basketball courts, etc.

Automotive industry: belts, floor mats for trains, brake disc belts, flooring for cars and trucks, brake linings, sealing belts, buffers, shock absorbers, etc.

Construction/equipment: adhesives, sealants, medical equipment, insulating rubber materials, carpet padding, used brake surfaces, moulded products, etc.

Civil engineering/asphalt: drainage pipes, filters, soil conditioning, road coverings, racecourses, railway crossings, etc.

Oil/gas industry: for pyrolysis into fuel oil, carbon black and combustible gas via the associated Beston pyrolysis plant.

Production of recycled rubber: for the production of various rubber products.

Guaranteed After-sales Services for you

Post-order Services

Once payment has been made, Beston will provide you with full tracking service for the tyre shredder, as well as installation, commissioning and staff training once the product is on the ground

Technical Consulting Services

If you encounter any problems with your tyre shredder during operation, you can call or email us immediately. Beston offers 24/7 online technical support for all customers.

One-year Shelf Life

Provide 1-year after-sales service free of charge. During this period, Beston will provide you with free maintenance services and free replacement of unqualified parts

Contact Us

Please fill in the form below and submit your inquiry. We will reply to you within 2 hours.

Please specify your requirement by referring to the following aspects:

1. What kind of solution will meet your demand? (Key point)

2. What kind of material and expected end product are you planning to have? (Right solution begins from material and product)

3. When is the project supposed to be running? (Key info for A-Z project programming)

4. Budget for machinery purchasing? (Key info for right model)

5. Points that you really focus on. (Customized service from our project consultant)