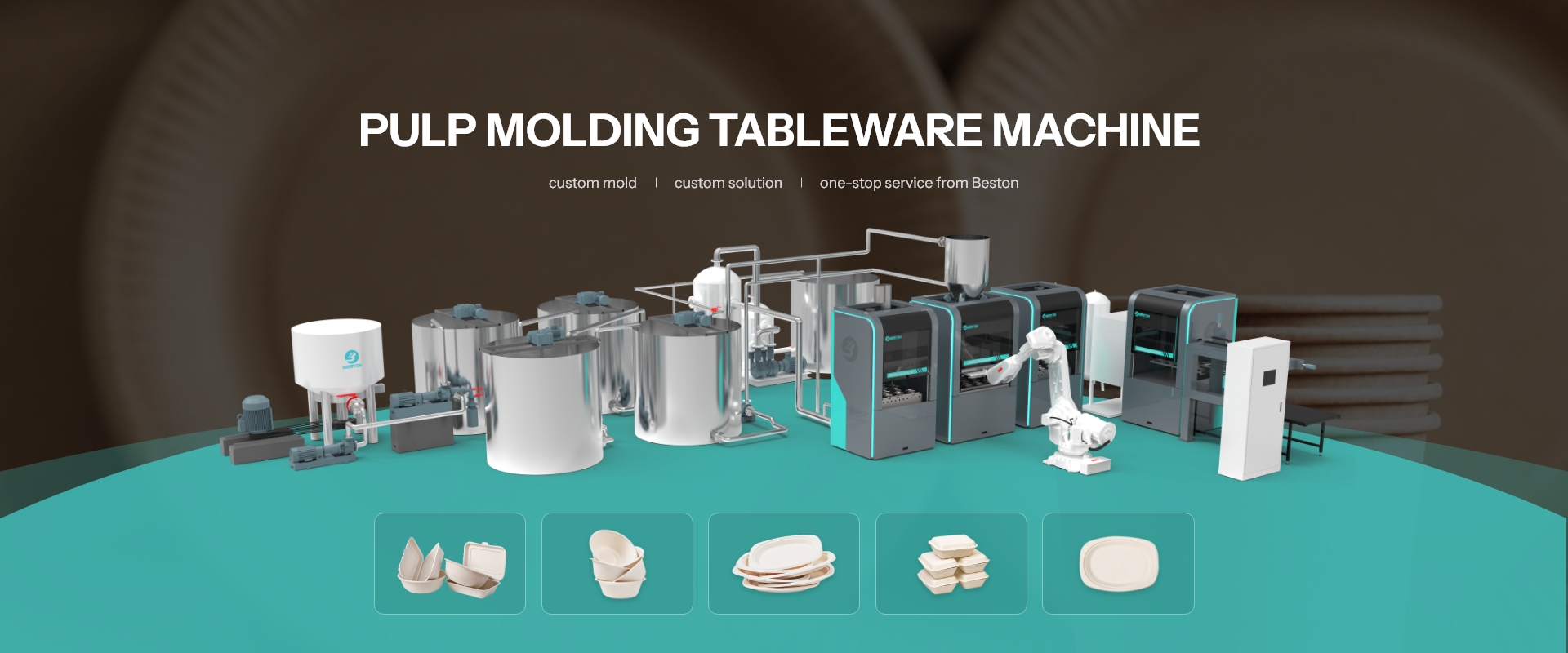

Pulp molding tableware machine enables you to make kinds of paper tableware with biomass or pulp board. It can greatly reduce our reliance on harmful plastic products. It is the ideal machine for the countries that are carrying out plastic bans. As a solution provider, we are good at supplying comprehensive service for you. So, if you are seeking a pulp molding tableware machine to make paper tableware, welcome to contact Beston Group!

Different Shapes of Pulp Tableware to Make

Beston pulp molding tableware machine can make different tableware. These pulp tablewares are disposable. Here are some common types of tableware that are used in daily life:

food bowls / food plates / food trays / food containers / tableware sets / fruit trays / cups lids

Application Scenario of Pulp Tableware

Pulp tableware has gained significant popularity as a sustainable alternative to traditional plastic or disposable tableware. Its eco-friendly and biodegradable properties make it an ideal choice for various settings. Here are the diverse application scenarios where pulp tableware finds its relevance and contributes to a greener future.

- Food Service Industry

- Takeaway and Delivery Services

- Hotels and Event Venues

- Educational Institutions and Corporate

- Retail Channels

- Events and Exhibitions

- Online Sales

Raw Materials to Make Tableware

Pulpboard:

Types of Pulp Molding Tableware Machine

Pulp molding tableware machines are mainly divided into semi-automatic tableware equipment and fully automatic tableware equipment. Here are the differences between both devices:

Semi-automatic Equipment

- Layout: reciprocating forming machine in the middle + two hot press machines on both sides;

- The mechanical structure is simple and easy to operate;

- The degree of automation is rather low. The manual transfer of paper molding tableware products is needed.

Automatic Tableware Equipment

- Add a multi-joint manipulator and trimming machine to the equipment;

- The forming system adopts a slurry suction design;

- The operation process is fully automatic until the trimming process is completed, and the products are collected manually.

| Name | Model | Capacity(23h) | Equipment Size | Wegiht | Tableware Height | Hot-press Pressure | Worker | Trimming | |

|---|---|---|---|---|---|---|---|---|---|

| Semi-automatic Tableware Machine | BCP-950 | 300-400KG | 4100*1200*2800 | 11T | 80-100mm | 40T | 1 | / | |

| Automatic Tableware Machine | BCP-950x | 600-800kg | 5400*2500*2800 | 16T | 80-100mm | 40T | 0 | 100T | |

Popular Models of Egg Tray Making Machine

To meet different production demands, Beston Egg Tray Making Machine provides five models for your choice. In addition, your choice can be based on the drying systen, such as brick drying or metal drying. But all machine adopts fully automatic system wgich can significantly improve production efficiency. Beston Egg Tray Making Machine price starts from $10,000 to $200,000 (price varies due to different models, configuration, capacity or drying method).

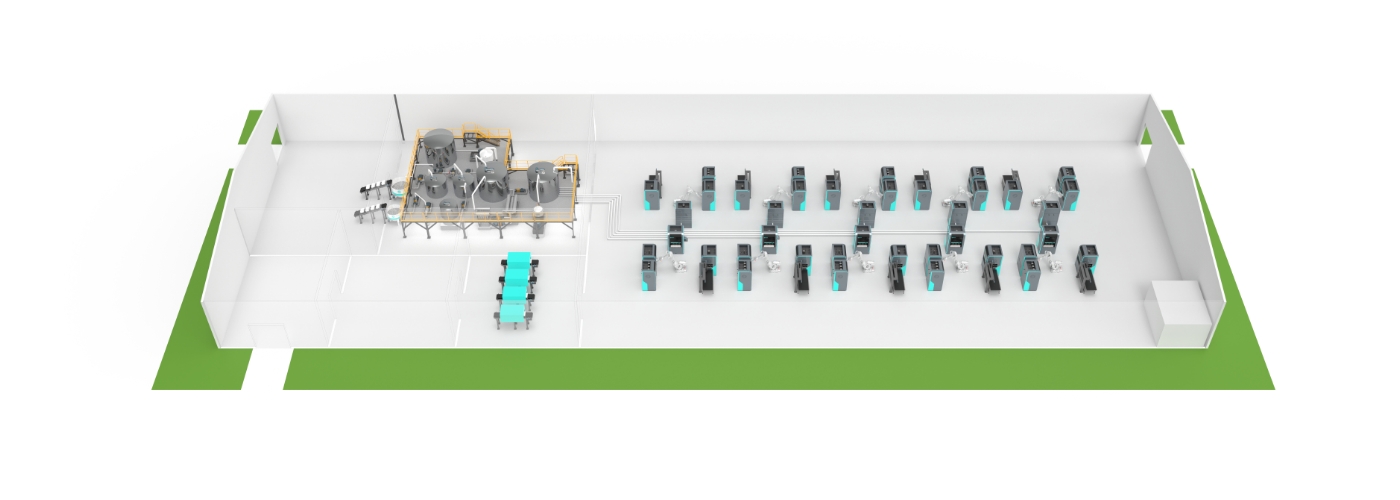

Layout Design – See Production Site Visually

Before manufacturing, Beston Group would confirm the site layout with you. From pulp making to tableware packaging, we provides standard configuration. Here, you can see the 3D layout design.

Advantages of Pulp Molding Tableware Machine

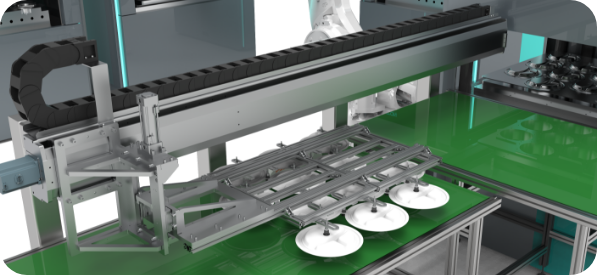

High Efficiency & Automation

- Self-developed control program – strictly control the time

- Multi-joint manipulator – Quick to transfer tableware;

- Fully automatic intelligent system

High Efficiency & Automation

- Self-developed control program – strictly control the time

- Multi-joint manipulator – Quick to transfer tableware;

- Fully automatic intelligent system

Easy Operation & Maintenance

- One step hot press and forming;

- Easy to change molds;

- Open type for easy maintenance;

High Quality End Product

- Fiber recycling system to increase finished product rate;

- High-pressure water cleaning system to improve the qualification rate of finished products;

Energy-saving Design

- Energy-saving frequency conversion control system

- New thermal insulation material – Save heat loss and energy consumption

- Pulp water can be used many times;

Automatic Pulping Control System

- Automatic intelligent control of pulping process

- IOT remote control

Superiority of Mold

- CAD/CAM

professional design capability

- Customized mold

meet your specific demand

- High precision

make standard size tableware

- Aluminium Sheet 6061

durability and longer lifetime

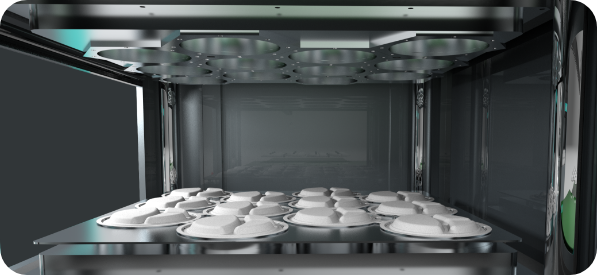

Working Process of Pulp Molding Tableware Machine

The sugarcane bagasse tableware making machine uses specific molds to process the fibrous biomass raw material into the proposed structural shape. Next, the products are finished and processed to make tableware products. It mainly includes dinner plates, dinner bowls, cup lids, lunch boxes, etc.

When the ground slurry enters the homogenizer tank, it is uniformly mixed with the waterproof and oil-proof agent. After the pulp is adjusted to a suitable concentration, it is pumped into the forming system;

After the formed product evaporates excess water through the drying system, it is shaped into a finished product;

Trimming the shaped pulp molded products by trimming machine to make the appearance of the finished product more exquisite;

Use the baler to pack the finished products, which is convenient for delivery and transportation.

Honor and Patent Certificates

High ROI of Pulp Molding Tableware Machine

| Analysis of BCP-950 Pulp Molding Tableware Production Line (Semi-automatic)2T/day | |||||

|---|---|---|---|---|---|

| based on Chinese price | |||||

| Material | Waste wood | 250KG/h | 8H | ||

| Waste water | 750KG/h | 8H | $0.32/T | ||

| Electricity | 100KW/h | 8H | $0.14/KWh | ||

| Labor | 4 Person/Shift | 1 Shift/Day | $7.5/person/day | ||

| Daily Input | |||||

| Item | Unit | Consumption | Unit Price | Total | Remark |

| WaterWater | T | 6 | $0.32 | $1.92 | Water is recycled in actual production |

| Electricity | KWh | 800 | $0.14 | $112 | |

| Labour | Person | 4 | $7.50 | $30.00 | |

| Depreciation | Day | 1 | $25.00 | $25.00 | |

| Other Expenses | Day | 1 | $20.00 | $20.00 | |

| $188.92 | |||||

| Daily Output | |||||

| Item | Unit | Quantity | Unit Price | Total | Remark |

| Sugarcane Bagasse Pulp Board | T | 2 | $1017.00 | $2034.00 | |

| Total | $2034.00 | ||||

| Daily Profit = Output – Input = $1845.08 | |||||

| Monthly Profit (30 Days) = $21845.08 * 30 = $55,352.40 | |||||

| Annual Profit (30 Days) = $55,352.40 * 12 = $664,228.80 | |||||

| Remarks: The cost and Profit analysis is according to the situation of China for reference. Different Clients need to analyze cost and profit according to your local situation. | |||||

Pulp molding tableware machine of Beston Group allows you to make paper tableware in a wide range of shapes and sizes. Paper packaging is becoming more and more popular across the globe. It is a sustainable and eco-friendly solution for the packaging industry. Therefore, join us to make a contribution to a greener and cleaner future.

Contact Us

Please fill in the form below and submit your inquiry. We will reply to you within 2 hours.

Please specify your requirement by referring to the following aspects:

1. What kind of solution will meet your demand? (Key point)

2. What kind of material and expected end product are you planning to have? (Right solution begins from material and product)

3. When is the project supposed to be running? (Key info for A-Z project programming)

4. Budget for machinery purchasing? (Key info for right model)

5. Points that you really focus on. (Customized service from our project consultant)