Charcoal Making Machine for Sale

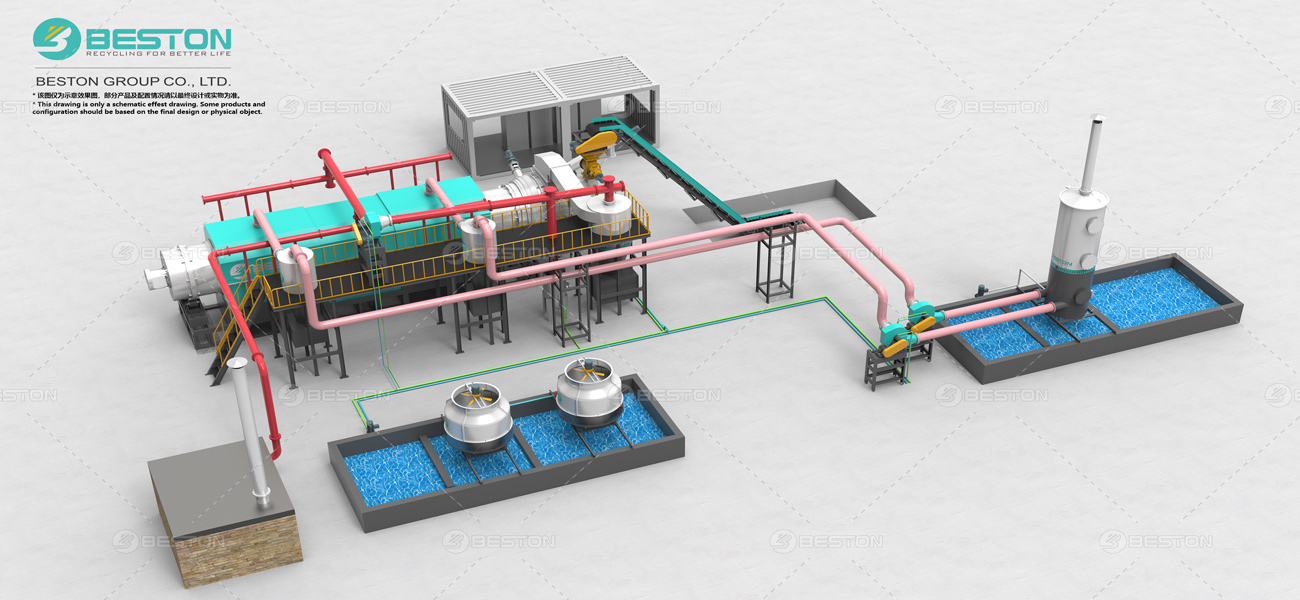

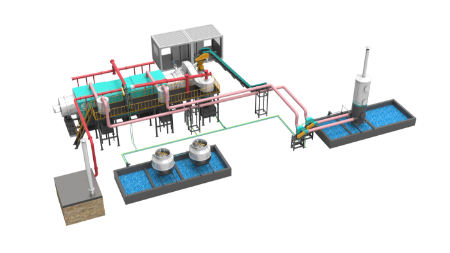

Production and Delivery of Carbonization Machine

- Delivery time: 2023

- Location: Indonesia

- Product model: BST-50 Carbonization Machine

- Operating efficiency: 15-25 tons /day

Installation method:

On-site installation

End product:

biochar

About Beston Charcoal Making Machine

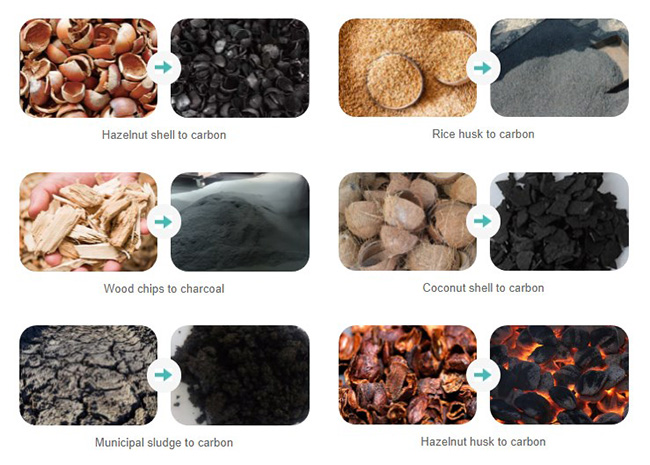

Biomass waste

Rice husks, coconut shells, palm kernel shells, bamboo, sawdust, olive shells, coffee husks, nut shells, hazelnut shells, oak, jute stalks, sugarcane bagasse, peanut shells, sunflower stalks, plant straw, peach pits, etc.

Sewage and sludge waste

Municipal sludge, river sludge, domestic sludge, etc.

Municipal solid waste

Waste battery graphite, cans, waste aluminum and other household waste, industrial waste, electronic waste, etc.

Charcoal

Further processed into BBQ carbon or activated carbon;

Used to make building bricks with clay;

To improve soil quality.

Wood vinegar

Used as insecticide;

To neutralize pesticides;

To improve soil quality.

Tar

To melt biodiesel;

Widely used in the production of waterproof and anti-corrosion materials.

Combustible gas

Used as fuel or for drying;

Used to produce electricity;

To heat greenhouse plants.

About Beston Charcoal Making Machine

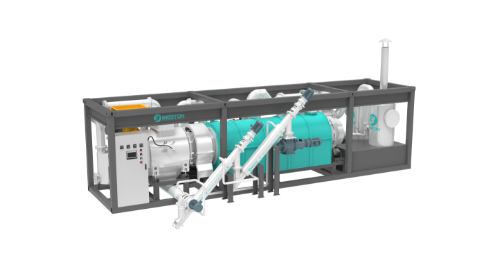

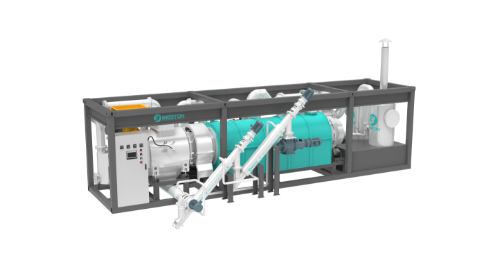

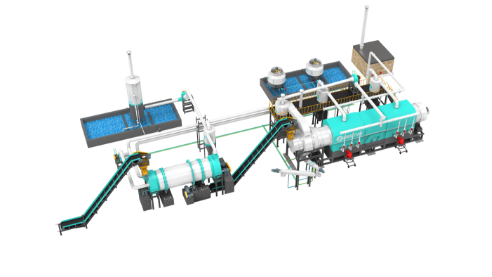

To improve the production efficiency and quality of biochar, Beston charcoal making equipment has three models: skid-mounted, batch and fully continuous, and their production capacity is 300 ~ 5000 kg per hour for your choice. Below we have listed 4 popular models of carbonization equipment, including their specific parameters.

BST-05 PRO Charcoal Making Machine

Model: skid-mounted

Feature: mobile type and easy to transport.

BST-05 PRO Charcoal Making Machine

Model: skid-mounted

Feature: mobile type and easy to transport.

BST-05 PRO Charcoal Making Machine

Model: skid-mounted

Feature: mobile type and easy to transport.

BST-05 PRO Charcoal Making Machine

Model: skid-mounted

Feature: mobile type and easy to transport.

Parameters about Beston Charcoal Making Machine

| Model | BST-J12 | BST-J18 | BST-J40 | BST-05 Pro | BST-10 | BST-30 | BST-50 |

| Input Capacity | 12 m³/batch | 18 m³/batch | 40 m³/batch | 0.3-0.5 m³/h | 2-4 m³/h | 7-9 m³/h | 10-15 m³/h |

| Reactor Size | φ1900 mm*L4500 mm | φ1900 mm*L6600 mm | φ2800 mm*L7100 mm | φ830 mm*L5500 mm | φ1300 mm*L14051 mm | φ1700 mm*L14180 mm | φ2000 mm*L14260 mm |

| Land for Equipment (L * W * H, Standard COnfiguration) | 9 m*6 m*6 m | 12 m*6 m*7 m | 15 m*18 m*7 m | 9.5 m*2.5 m*3 m | 25 m*15 m*7 m | 30 m*15 m*7 m | 35 m*15 m*8 m |

| Weight (Standard Configuration) | 18 T | 22 T | 34 T | 15 T | 32 T | 35 T | 49 T |

| Energy Consumption (Standard Configuration) | 11 kw/h | 13.5 kw/h | 25 kw/h | 31 kw/h | 34.7 kw/h | 61.5 kw/h | 116 kw/h |

| Working Method | Batch | Fully continuous | |||||

| Feeding Requirement | / | Size: ≤20mm; moisture: ≤15%; strong liquidity | |||||

| Structure | Horizontal rotation | DOuble barrel single hearth | Double barrel double hearth | ||||

| Speed | 0-2 RPM | 1-9 RPM | |||||

| Control Method | Control by buttons | Automatic control | |||||

| Reactor Material | Q245R | Q245+310S | |||||

| Pressure | Micro negative pressure | ||||||

| Heating Material | Diesel, natural gas, heavy oil, biomass, etc. | ||||||

| Heating Method | Direct heating | ||||||

| Noise(dB) | ≤80 | ||||||

| Condenser | Circulating water cooling | ||||||

| Rotation Method | External gear rotation | ||||||

Note: Here is the production capacity about rice husk raw material for reference. Production capacity varies from different raw materials. If you want to know more reference data, please contact us.

Cost and ROI of Beston Charcoal Making Machine

| Return on Investment of BST-50 Olive shells Carbonization Project | ||||||

| Introduction | Product market data, the details of different costs are as follows: | |||||

| Based on Turkey price | ||||||

| Category | Material | Olive shells | 120MT/Day | $200/MT | ||

| Fuel | Natural Gas | 270m³//Day | $1.25/M | |||

| Electricity | 102KW/H | 24H | $0.11/KWH | Daily consump 1713kw | ||

| Labor | 5 Person/shift | 1Day | $16.8/person/day | |||

| Charcoal | 30% charcoal yield | 36MT | $2000/MT | |||

| Wood veneger | 8% yield | 9.6MT | ||||

| Tar Oil | 4% yield | 4.8MT | ||||

| Introduction | ltems | Unit | Consumption | Unit price | Total | Remark |

| Daily Input | Olive shells | MT | 120 | $200.00 | $24,000.00 | |

| Natural gas | m³ | 270 | $1.25 | $337.50 | ||

| Electricity | KWH | 1713 | $0.11 | $188.43 | ||

| Labor | Person | 3 | $16.80 | $50.40 | ||

| Depreciation | Day | 1 | $25.00 | $25.00 | ||

| Other expenses | Day | 1 | $21.00 | $21.00 | ||

| $24,622.33 | ||||||

| Introduction | Itemns | Unit | Quantity | Unit price | Total | Remark |

| Daily Output | Charcoal | MT | 36 | $2,000.00 | $72,000.00 | Remarks:The cost and profit analysis is according to the Turkey market for reference.Different Clients need to analyze cost and proft according to your local market |

| Wood venegar | MT | 5.1 | ||||

| Tar Oil | MT | 1.8 | ||||

| $72,000.00 | ||||||

| Daily Income | ||||||

| Output – Input | $47,377.67 | |||||

| Monthty Profits (25 days) | $1,184,441.75 | |||||

| Annual Profits (10 Months) | $11,844,417.50 | |||||

Note: Here is the production capacity about rice husk raw material for reference. Production capacity varies from different raw materials. If you want to know more reference data, please contact us.

Work Flow of Beston Charcoal Making Machine

.gif)

Drying stage

Endothermic pyrolysis stage

The temperature is 220-270℃, and the raw materials begin to decompose and release gaseous products, the chemical composition of the raw materials begins to change, and the temperature at which different materials begin to pyrolyze is different.

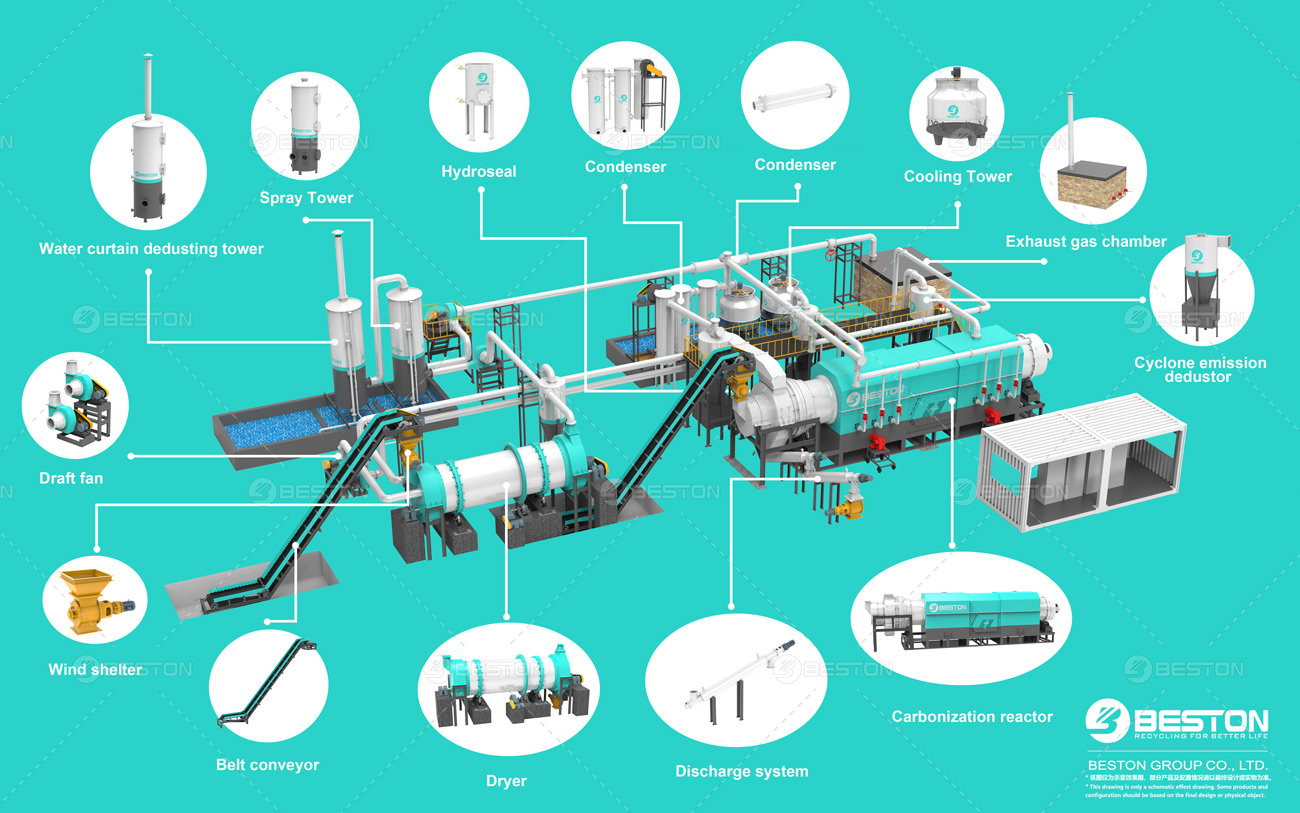

Components about Beston Charcoal Making Machine

Safety Design

Explosion-proof hole, explosion-proof water seal and alarm device equipped to ensure security .

Eco-friendly Design

Double barrel body to improve heat efficiency, and achieve good energy saving performance, which gain industry customers.

Energy-saving Design

Double barrel body design is used to make heat efficiency higher, and the use of air exchanger can effectively improve the thermal efficiency by 5-10%.

Real-time Monitoring

Internet of things function to monitor product usage, operating parameters, faults and other information in real time.

Components about Beston Charcoal Making Machine

Production and Delivery of Carbonization Machine

- Delivery time: 2023

- Location: Indonesia

- Product model: BST-50 Carbonization Machine

- Operating efficiency: 15-25 tons /day

Installation method:

On-site installation

End product:

biochar

Production and Delivery of Carbonization Machine

- Delivery time: 2023

- Location: Indonesia

- Product model: BST-50 Carbonization Machine

- Operating efficiency: 15-25 tons /day

Installation method:

On-site installation

End product:

biochar

Production and Delivery of Carbonization Machine

- Delivery time: 2023

- Location: Indonesia

- Product model: BST-50 Carbonization Machine

- Operating efficiency: 15-25 tons /day

Installation method:

On-site installation

End product:

biochar

Production and Delivery of Carbonization Machine

- Delivery time: 2023

- Location: Indonesia

- Product model: BST-50 Carbonization Machine

- Operating efficiency: 15-25 tons /day

Installation method:

On-site installation

End product:

biochar

Components about Beston Charcoal Making Machine

Brand Advantages of Beston

- Customer-oriented

- Top 3 in the carbonization industry

- 200,000-square-meter factory scale

- Professional staff

- Advanced technology

- Rich industry experience

Components about Beston Charcoal Making Machine

Pre-sale Service

- Focus on customer’s demands: details communication and optimal solution providing for choice;

- Focus on customer’s demands: details communication and optimal solution providing for choice;

- Focus on customer’s demands: details communication and optimal solution providing for choice;

- Focus on customer’s demands: details communication and optimal solution providing for choice;

Pre-sale Service

- Focus on customer’s demands: details communication and optimal solution providing for choice;

- Focus on customer’s demands: details communication and optimal solution providing for choice;

- Focus on customer’s demands: details communication and optimal solution providing for choice;

- Focus on customer’s demands: details communication and optimal solution providing for choice;

Pre-sale Service

- Focus on customer’s demands: details communication and optimal solution providing for choice;

- Focus on customer’s demands: details communication and optimal solution providing for choice;

- Focus on customer’s demands: details communication and optimal solution providing for choice;

- Focus on customer’s demands: details communication and optimal solution providing for choice;

Contact Us

Please fill in the form below and submit your inquiry. We will reply to you within 2 hours.

Pre-sale Service

Please specify your requirement by referring to the following aspects:

1. What kind of solution will meet your demand? (Key point)

2. What kind of material and expected end product are you planning to have? (Right solution begins from material and product)

3. When is the project supposed to be running? (Key info for A-Z project programming)

4. Budget for machinery purchasing? (Key info for right model)

5. Points that you really focus on. (Customized service from our project consultant)